- PVC Waterstops - Levajoint & Rayjoint

- Accessories for precast and in-situ cast concrete, for reinforcement, formwork and general contracting - Levafix

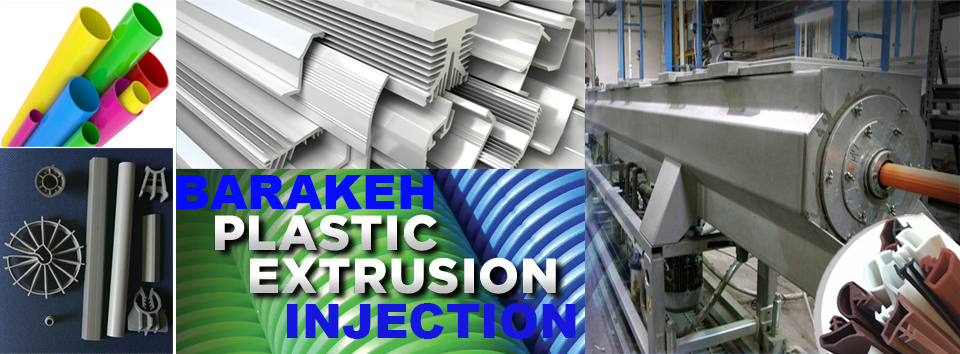

- Profiles (Tubes, Chamfer, Trapeze, Joint rule...) - Levaprofile

- More than 550 Soft & Rigid profiles geared mainly to the following sectors: Wood, Aluminium, Metal, Construction, Car & Furnishing Industries - Levatrim

- PVC Spiral reinforced flexible hoses from ½" up to 8 " - LEVAFLEX

- PVC non reinforced hoses, for gardens, homes from ½" up to 1 ½" - LEVAGARDEN

- PVC non reinforced hoses, used as channels (transporting mainly water without using pressure), produced in internal diameter 2 up to 6 inches - LEVAFLAT

- Polyethylene Low Density (PE-LD) used for electric wires installation - LEVACABLE Polypropylene Random Copolymer (PP-RC) used for under floor heating - LEVAHOT

- PVC Ducting Hoses for ventilation and aeration - LEVADUCT

- PVC Pipes & Tubes for electrical conducts and water drains - LEVAPIPE

- Polyethylene Low Density & High Density (PE-LD and PE-HD) pipes for drip irrigation produced from 12 up to 110 mm external diameter - LEVATHEN

Flexible

Rigid

Shapes

Standards & Norms

Professional

Plastics generally have:

| • Resistance to corrosion and chemicals |

| • Low electrical and thermal conductivity |

| • High strength-to-weight ratio |

| • Colors available in a wide variety and transparent |

| • Resistance to shock |

| • Good durability |

| • Low cost |

| • Easy to manufacture |

| • Resistant to water |

| • Low toxicity |

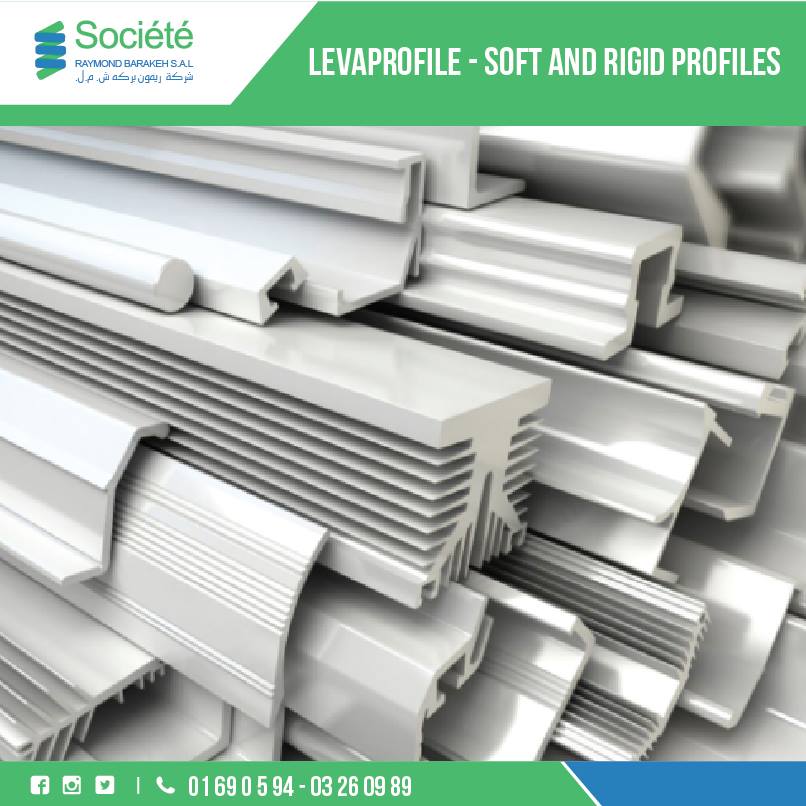

We primarily extrude PVC (Rigid & Flexible), PE-LD, PE-HD, PP-RC and TPV. ‎

Yes, we can match any color you need in all materials we extrude with in-house color processing.‎

As a manufacturer of custom plastic extrusion profiles, we serve many different industries. We ‎work closely with our customers to provide the highest quality thermoplastic extrusions, whether ‎for construction, furniture, industrial or other markets.‎

Yes we can. Our staff has many years of experience in extrusion but we can provide some ‎assistance to every industry that we serve.‎

Ordered items can be delivered within 24 hours on a (First-come, First-served) basis. Custom runs ‎vary depending on raw material availability and current backlog, which is typically 3-4 weeks at ‎most.‎

Yes, we can always schedule a custom run to whatever length you need.‎

Material granules for the part is fed via a hopper into a heated barrel, melted using heater bands and the frictional action of a reciprocating screw barrel. The plastic is then injection through a nozzle into a mold cavity where it cools and hardens to the configuration of the cavity.

Common thermoplastics used in injection molding are: Acrylonitrile Butadiene Styrene (ABS). Polyethylene (PE). Polycarbonate (PC). Polyamide (Nylon). Polyvinyl Chloride (PVC). High Impact Polystyrene (PS). Polypropylene (PP).

Levacable - Electric Cable Conduits

Levaclear - Clear Garden Hoses

Levadrip - PE Drip Irrigation Pipes

Levafix - Spacers & Accessories

Levaflat - Flat PVC Non Braided Hoses

Levaflex - PVC Reinforced Flexible Hoses

Levafop - Smooth Interior Pliable Conduits for Optical Fibers Cables

Levahot - PPRC Flexible Pipes for Hot Water Networks

Levaseal - Omega Sealing Joints

Leva ‎Tilepad - Base for prefabricated slabs